|

e layout and specification e layout and specification

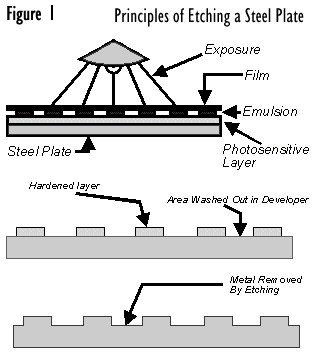

normally, an "open tech" cliche is etched to a depth of 25 microns, 2. deeper or shallower etches can be achieved. however, etch depths greater than 30 microns with conventional organic inks can cause spreading and feathering of the printed image.

more than one image can be etched on a cliche, and most pad-printing machines can be adjusted to pick a specific image from a larger plate. if you are responsible for deciding on a cliche layout, be sure that the images are positioned in such a way that when the pad compresses, it does not go outside the plate area and pick up extraneous ink. also, be sure to leave a gap of no less than 15 mm (0.6 in.) between the outer edges of the image and the edge of the plate.

special metal cliches

multicolour -- allow more than one colour to be printed from a single cliche using multiple pads. some presses use separate cliches that can be individually adjusted to position the colours.

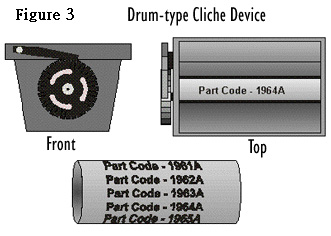

product encoding -- when products need to be coded with date, part number, or other sequential information, repositioning the cliche for each code can be impractical. one solution is to use a fixed plate holder with narrow sliding plates that can be quickly adjusted into various combinations. (figure 2)

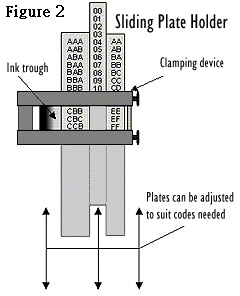

another option for printing multiple product codes is to empty a plate-indexing system. figure 3 shows a drum-type cliche device, which allows the user to quickly advance to the next code.

this type of work can also be handled be sophisticated, computerized, numerically controlled presses. through computerized controls, the press can adjust the pad pick-up position to ensure that the desired image from the plate is picked up each time. such machines have been used to print small quantities of items such as specialized keyboards.

other types of cliches

thin steel cliches -- reduce the cost of etched steel plates. these are very flat with thickness of about 2 mm, but not as hard as conventional steel plates.

photopolymer cliches -- consist of a steel base plate laminated with a photopolymer relief layer that is shielded from light with protective film.

mechanically engraved plates -- a very cheap method of producing short-run plates. artwork and positives are unnecessary. it can be cut to fit the size of your press.

cleaning and storage of etched metal cliches

always remove all traces of ink (particularly from the etch) during any breaks in production, such as lunch, coffee breaks, overnight, etc. take extra care when using two-part inks, which are almost impossible to remove if they cure in the etching.

store metal cliches in a dry area with a thin film of oil or grease on the surface. wrap the cliches in the corrosion-inhibiting paper supplied by your plate vendor. be sure that all traces of ink have been removed from the cliche before you do this. do not stack one cliche on top of another unless you are certain all ink has been removed.

cliches can be stored on end in a wooden magazine separated by partitions. although they are extremely hard, be careful not to bring the cliches into contact with each other because the corner of one plate could indent the surface of another.

remember the four key elements of getting quality results from your cliches:

1. be sure the positives are correct.

2. verify that the etch depth is correct and consistent, with no faults in the image.

3. use as little pressure on the doctor blade as possible.

4. clean the cliche before storage and keep it away from moisture.

carol burnside

carol burnside works as a pad and screen printing consultant. together with peter kiddell, they run product decoration services, a company that develops training packages to help companies fine tune their pad printing process. carol and peter, may be contacted at: |